Q&A: Teenage Engineering

The Swedish synthesizer firm unveils its low-cost Pocket Operators.

Since unveiling its OP-1 portable music production machine in 2010, the Stockholm, Sweden-based Teenage Engineering has become something of a phenomenon in the electronic music world. The OP-1 meshed elegant, stripped-down industrial design with wildly inventive musical tools, carving out an adoring niche of electronic producers in the process.

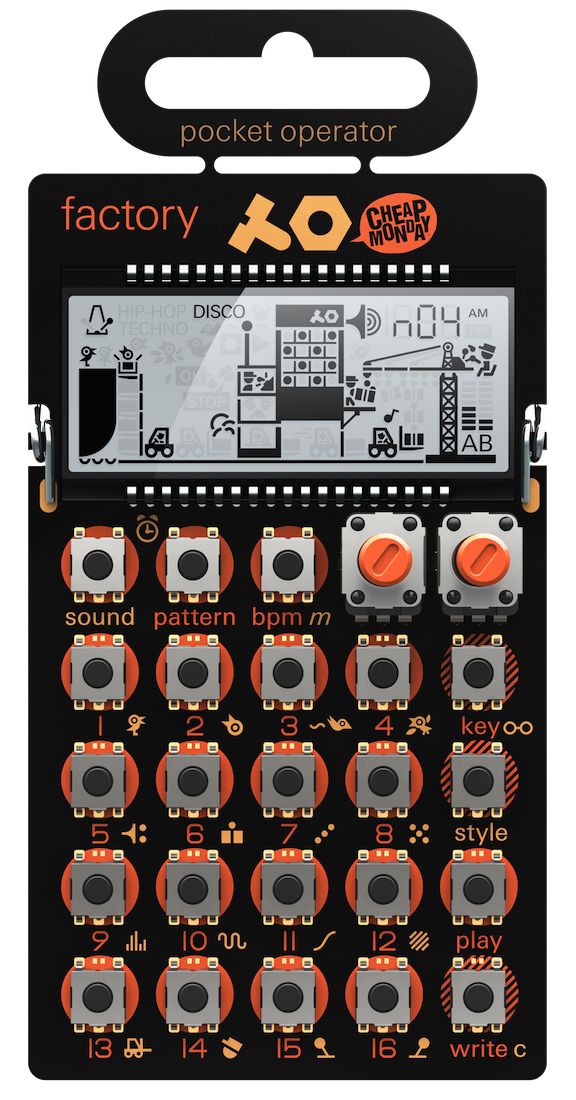

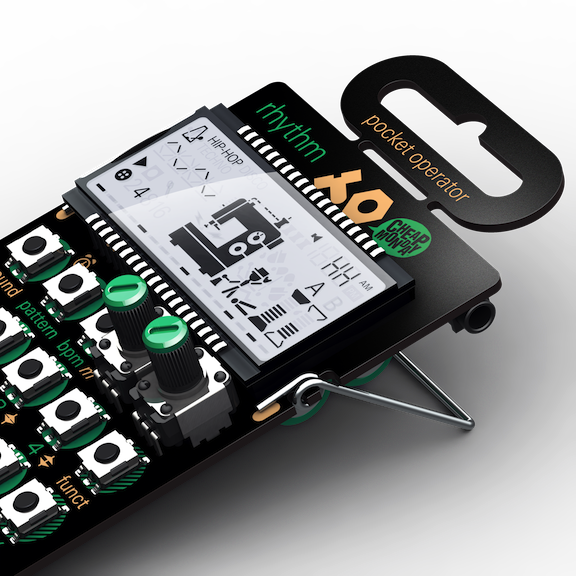

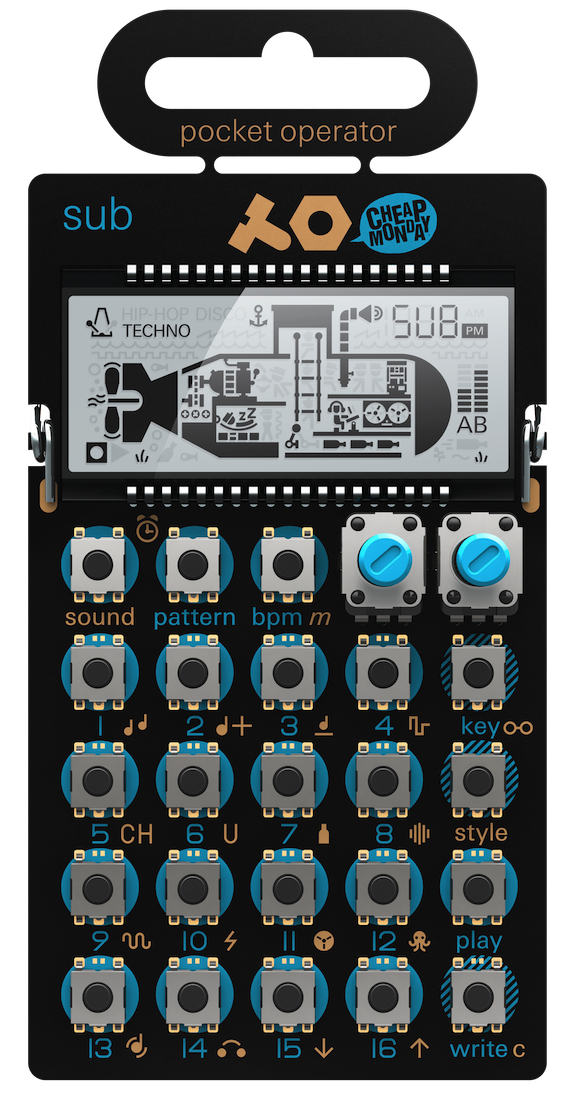

Where the OP-1 comes in at a fairly hefty $849, the company’s most recent release hits a price point ready for mass consumption. The trio of Pocket Operators includes a drum machine (PO-12 Rhythm), a bass synth (PO-14 Sub) and a melody maker (PO-16 Factory), and each is small enough to come with you everywhere. Each device costs $59, with exposed printed circuit boards making up the majority of their interface; silicon cases are sold separately, tidying things up a bit and providing some added durability. The sounds they emit are far bigger than their diminutive frames, and all three can be tempo synced via 1/8” headphone cables. We spoke with a couple of the folks at Teenage Engineering about how the Pocket Operators came together.

You’ve said that the idea behind the Pocket Operators came from a desire to “return the favor” to Cheap Monday. What was that favor?

Emil Kullänger: The idea of the collaboration between Teenage Engineering and Cheap Monday was born in the autumn of 2013. The engineers needed new, protective, lab coats for the staff, and instead of buying generic ones our creative director, Jesper Kouthoofd, turned to his longtime friend Ann-Sofie Back, asking Cheap Monday to design a unique coat and additional garments for his team. Cheap Monday took on the challenge but asked for a return favor; what began with the engineers’ need for new lab wear grew into a project, where a line of portable synthesizers and matching gear were born in a unique collaboration between the two brands.

In an interview with TE several years back about the OP-1, it was mentioned that the device was meant to be as accessible and affordable as possible, but that manufacturing simply ended up being too expensive to meet that latter goal. Are the Pocket Operators at all an attempt to reach that goal?

Kullänger: You could say that. We had an idea of the price point we wanted it to have, and worked hard to get as much as possible within all limits. We [even] built in the hanger for store displays to save money.

You also mentioned that the Pocket Operators concept initially started as an app. Why did you end up steering away from this and into a hardware-based approach?

Kullänger: At one of the first meetings, we were brainstorming about what product or products we could make, and a lot of ideas crossed our minds—everything from technical clothing to a hybrid software/hardware cover for cell phones, among many many other ideas. Then we decided to do what we love most: hardware.

How did the Pocket Operators case competition come about?

Kullänger: The case competition was an idea from our similar campaign we did for the OP-1 accessories. It’s very fun to see what people can come up with for hacks. We like to support that innovative culture—it all keeps the product alive.

What in particular were the toughest aspects of development of the Pocket Operators, in regards to keeping down the size and the price of the devices?

Oscar Ahlgren: The hardest part was making the decisions to remove features, and limiting the design because size and cost was a driving factory. Adding features and components is easy—removing them is the hard part.

Was the emphasis on user-triggered effects something that came about because of this process?

Ahlgren: No, this actually came about pretty early, as soon as we knew what kind of CPU/flash we had to play with. Although we knew from the start that we wanted to sequence effects, we have parameter locks so really we probably would have done it just the same way even if we had a more powerful MCU.

What were some of the features you guys had to remove in the end?

Ahlgren: Ha ha…a bunch of stuff that we will incorporate into new products.

What would you say are the cornerstones of Teenage Engineering’s designs?

Ahlgren: I would say that our design has a “no fuzz” philosophy, with as little design as possible. Simple geometry, basic color palette, and accommodating for everyone.

The animations playing on the PO screens are fun and weird. How did these get conceived? Was there any idea to make the information on the screens more “functional”?

Ahlgren: During the early stages we had prototypes without LCDs, even though the plan was always to have them. But the UI and how to operate the [devices] came about before the LCDs were on the boards, so we kind of made it work without the LCDs. This made room for making the LCDs more fun, instead of purely functional.

You guys do a lot of prototyping in-house. What kind of machinery do you have in that wondrous Swedish garage? What’s been the most useful on PO development?

Kullänger: Among others we have a high definition 3D printer, a laser cutter, CNC router, etc. The most useful, in all projects, is definitely the laser cutter. We use it for everything, mostly making mockups of new products.—as was also the case with the Pocket Operators’ development.

What’s your favorite hidden function on the POs that most people don’t know about?

Ahlgren: Well, if you solder wires between buttons, speaker output, etc., on the back of the devices, some interesting things start happening.…